The petrochemical industry serves as a critical backbone of the modern world, providing an array of essential products that drive various sectors of the global economy. From plastics and synthetic fibers to pharmaceuticals and fertilizers, petrochemicals have become indispensable in our daily lives. However, alongside their undeniable contributions, this industry also faces challenges in managing emissions and pollutants. This blog explores the significance of the petrochemical sector, the impact of its emissions, and the innovative role that dry scrubbers play in reducing environmental harm.

The Importance of the Petrochemical Industry

The petrochemical industry plays a fundamental role in transforming crude oil and natural gas into an astonishing range of products. Ethylene, propylene, benzene, and methanol are just a few of the primary building blocks used to create an extensive array of chemicals, plastics, and synthetic materials. Additionally, the sector is an essential provider of energy sources like gasoline, diesel, and aviation fuel.

Despite these indispensable contributions, the petrochemical industry faces environmental challenges due to the emission of harmful gases and particulates during its manufacturing processes. These emissions contribute to air pollution, climate change, and other adverse ecological impacts.

Understanding Dry Scrubbers

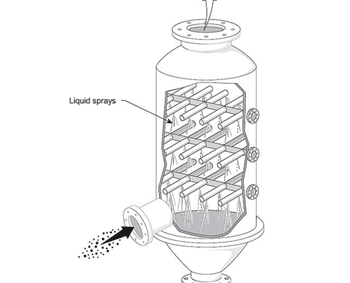

Dry scrubbers stand as a cutting-edge solution to address air pollution stemming from industrial processes like petrochemical production. They are advanced air pollution control devices designed to remove pollutants from exhaust gases before they are released into the atmosphere.

Dry scrubbers operate by injecting a sorbent, such as hydrated lime (calcium hydroxide) or sodium bicarbonate, into the flue gas stream. As the gas passes through the scrubber, the sorbent reacts with acidic pollutants like sulfur dioxide (SO2) and hydrogen chloride (HCl). This chemical reaction neutralizes the acids, converting them into harmless salts or solid particles. The cleaned gas can then be safely released into the environment.

Applications of Dry Scrubbers in the Petrochemical Industry

Sulfur Dioxide (SO2) Removal: During the production of sulfur-containing compounds like sulfuric acid or various polymers, the petrochemical industry releases significant amounts of sulfur dioxide. Dry scrubbers effectively capture and neutralize SO2 emissions, preventing them from contributing to acid rain and respiratory problems.

Hydrogen Chloride (HCl) Abatement: Petrochemical processes often release hydrogen chloride, a highly corrosive gas that poses significant risks to human health and the environment. Dry scrubbers aid in capturing HCl emissions, mitigating their negative impacts.

Particulate Matter (PM) Control: Petrochemical plants can release various particulates during their production processes. Dry scrubbers help trap these particles, preventing them from dispersing into the air and reducing respiratory and environmental hazards.

Volatile Organic Compounds (VOCs) Removal: VOCs are a group of hazardous chemicals often emitted by petrochemical facilities. Dry scrubbers can play a role in removing these compounds from the exhaust gases, helping to reduce smog and ground-level ozone formation.

Benefits of Dry Scrubbers

The use of dry scrubbers in the petrochemical industry offers numerous advantages, including:

Environmental Protection: By effectively reducing harmful emissions, dry scrubbers contribute to improved air quality and reduced environmental impact.

Compliance with Regulations: Many countries have strict regulations regarding industrial emissions. Dry scrubbers assist petrochemical companies in meeting these regulatory standards.

Cost-Effectiveness: Dry scrubbers are a cost-efficient solution for pollution control, reducing the need for expensive downstream treatments of emitted gases.Unlike wet scrubbers that use water to neutralize pollutants, dry scrubbers require little to no water, making them a more sustainable option.